Description

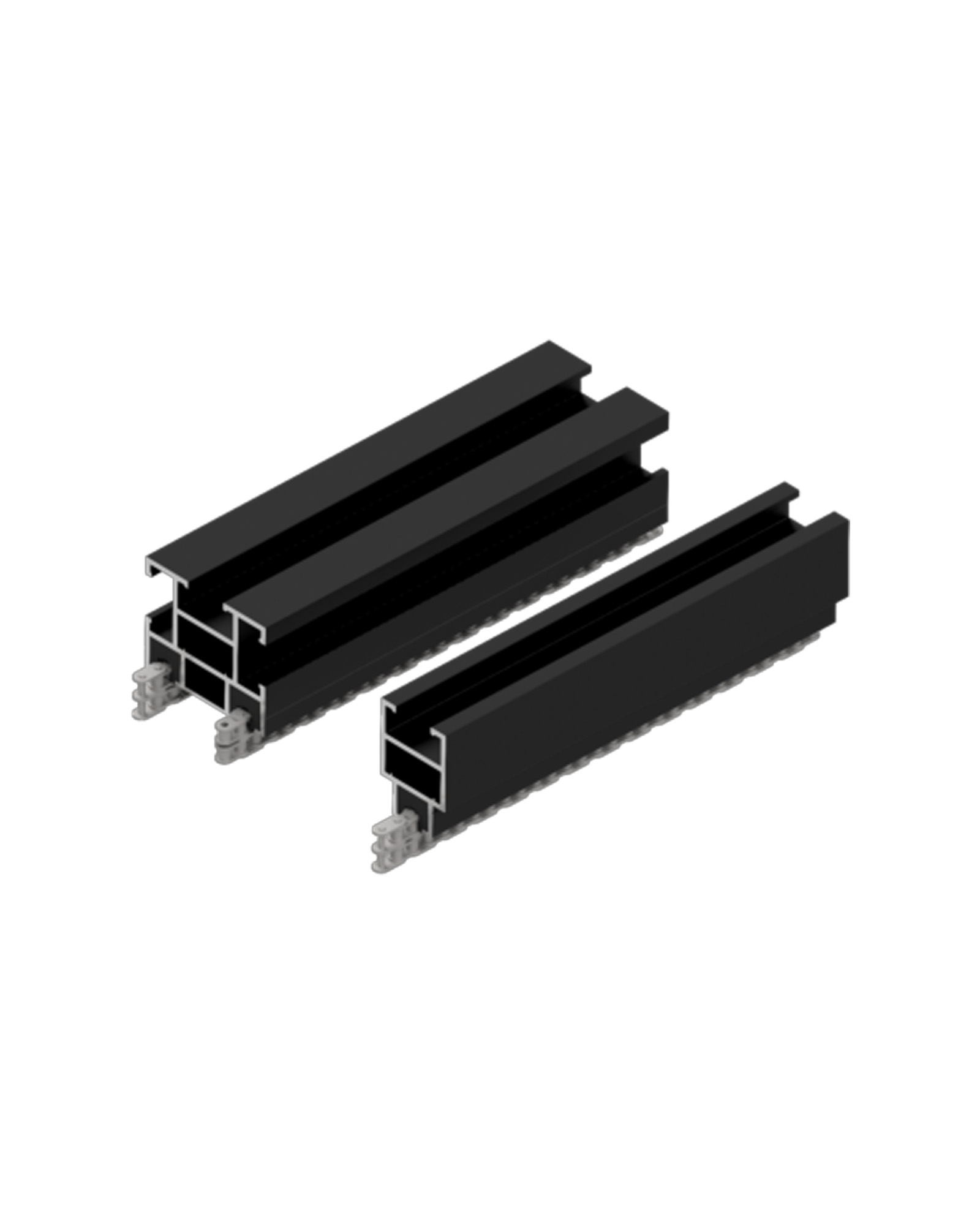

Triple E Chaintrack

The perfect solution for tight spaces, continuous operation and hiding a large curtain in a compact stacking area. Equally at home in entertainment, art and retail environments, ChainTrack allows architect’s ideas to be realised.

ChainTrack is an aluminium extrusion, chain driven system with a load capacity of 20 kg per metre. Compact stacking areas, a minimum radius of 30 mm and low maintenance make ChainTrack the ideal solution for heavy duty cycle systems, decorative drapes that need to travel flat and large drapes that need to be hidden from sight quickly, neatly and quietly. Chain is a non-slip drive system which allows precise, repeatable positioning with encoders.

Combining ChainTrack’s standard extrusion and carriers with metalwork, motors and control designed for each project Triple E can create bespoke systems at competitive prices for complex specifications.

Key Points

- Satin black or mill finish

- Low maintenance

- Custom designed systems for each project

- Stocked in 6.1 m (20′) lengths

- Minimum radius of 30 mm

- Spiral or serpentine stacking areas.

Overview

The CHAIN TRACK system consists of a machined UHMW section, which carries the upper portion of a 3/8” duplex roller chain.

The UHMW is inserted into an aluminium extruded profile designed by and exclusively extruded for Triple E.

The permissible loading for curtains directly attached to the chain is 20kg (44 lbs.) per linear metre or 6kg (13.2 lbs.) per linear foot.

Specification

Chain track systems have a 3 phase motor of at least 0.4kW power increasing according to the predicted carrying and frictional loads.

The motor is normally located in the stacking / storage areas but can be mounted at the opposite end of the track or, where there are height constraints, the motor can be side mounted and hung beneath the track. The motors transmit power through a chain sprocket driving the upper section of the duplex chain.

The lower section of chain is used to carry the curtains.

The curtains will attach to the chain every 95mm by means of a purpose designed stainless steel hook and metal wire strop which locates through the eyelets in the curtain webbing.

At the far end of each track will be a return chain sprocket and tensioner, which should have a means of access to it for maintenance purposes.

In the storage / stacking areas, the CHAIN TRACK will run back and forth providing a stacking distance equal to that of the curtain length.

In the stacking area the extrusion carries a single chain and can be set on varying centres based on standard chain sprocket sizes, to provide adequate spacing between the travelling curtain fabrics of differing fullness and to reduce wear on the surface of the fabric caused by rubbing.

All chain sprockets have two ball raced bearings and are of a similar type to those proven on our test track to have a life expectancy in excess of 50,000 cycles based on a 25metre long track. There will be a timing belt driven limit box adjacent to the gearbox for setting the extreme end of travel limits.

In addition as a safety feature there will be two mechanical track mounted limits next to the motor and able to be struck by a clamp on the lower portion of the chain. This will ensure that in the event of a limit box failing there is a secondary means of stopping the curtain.

It is recommended that all control systems feature either variable speed or soft start features.

This is especially important on long systems to avoid chain snatch on start up. There is provision for the mounting of an encoder on the gearbox output if required.